What industries do tantalum capacitors include?

What Industries Do Tantalum Capacitors Include?

I. Introduction

Tantalum capacitors are a type of electrolytic capacitor that utilize tantalum metal as the anode material. Known for their high capacitance density and reliability, these capacitors play a crucial role in modern electronics. As technology continues to advance, the demand for tantalum capacitors has surged across various industries. This blog post will explore the composition, characteristics, and advantages of tantalum capacitors, as well as the key industries that utilize them, emerging trends, challenges, and future prospects.

II. Understanding Tantalum Capacitors

A. Composition and Characteristics

Tantalum capacitors are made from tantalum powder, which is sintered to form a porous anode. This anode is then coated with a dielectric layer of tantalum pentoxide, which is formed through an electrochemical process. The unique properties of tantalum, including its high melting point and excellent corrosion resistance, make it an ideal material for capacitors.

1. **Material Properties of Tantalum**: Tantalum is a rare metal that exhibits exceptional stability and resistance to oxidation. Its ability to form a thin oxide layer allows for high capacitance in a compact size.

2. **Electrical Characteristics**: Tantalum capacitors are known for their low equivalent series resistance (ESR) and high voltage ratings, making them suitable for applications requiring stable performance under varying conditions.

B. Advantages of Tantalum Capacitors

Tantalum capacitors offer several advantages over other types of capacitors, which contribute to their widespread use in various applications.

1. **High Capacitance Density**: Tantalum capacitors can achieve high capacitance values in small packages, making them ideal for space-constrained applications.

2. **Stability and Reliability**: These capacitors maintain their performance over a wide range of temperatures and voltages, ensuring consistent operation in critical applications.

3. **Temperature and Voltage Tolerance**: Tantalum capacitors can operate effectively in extreme conditions, making them suitable for demanding environments.

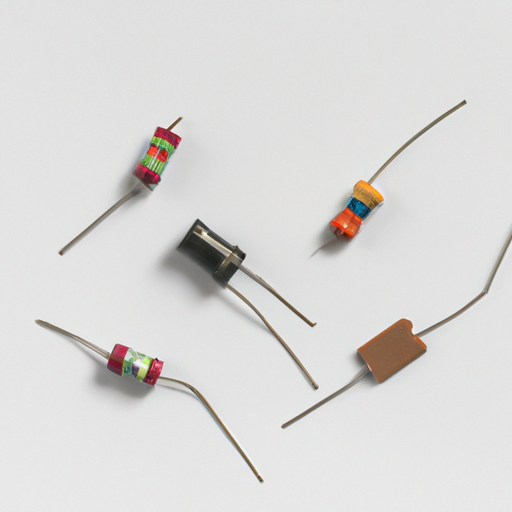

C. Common Applications of Tantalum Capacitors

Tantalum capacitors are commonly used in various electronic devices, including power supply circuits, filtering applications, and timing circuits. Their reliability and performance make them a preferred choice in many high-performance applications.

III. Key Industries Utilizing Tantalum Capacitors

Tantalum capacitors are integral to numerous industries, each leveraging their unique properties to enhance product performance and reliability.

A. Consumer Electronics

The consumer electronics industry is one of the largest markets for tantalum capacitors. These components are found in:

1. **Smartphones and Tablets**: Tantalum capacitors are used in power management circuits, audio systems, and RF applications, contributing to the compact design and functionality of these devices.

2. **Laptops and Desktops**: In computing devices, tantalum capacitors are essential for power supply circuits, ensuring stable voltage and efficient operation.

3. **Wearable Technology**: The miniaturization of electronics in wearables necessitates the use of high-capacitance, space-saving components like tantalum capacitors.

B. Automotive Industry

The automotive sector has increasingly adopted tantalum capacitors, particularly with the rise of electric vehicles (EVs) and advanced driver-assistance systems (ADAS).

1. **Electric Vehicles (EVs)**: Tantalum capacitors are used in battery management systems and power electronics, where reliability and performance are critical.

2. **Advanced Driver-Assistance Systems (ADAS)**: These systems rely on tantalum capacitors for stable operation in sensors and control units, enhancing vehicle safety and performance.

3. **Infotainment Systems**: Tantalum capacitors support the complex electronics in modern infotainment systems, ensuring high-quality audio and video performance.

C. Telecommunications

The telecommunications industry relies heavily on tantalum capacitors for various applications:

1. **Base Stations and Network Infrastructure**: Tantalum capacitors are used in power supply circuits and signal processing, ensuring reliable communication.

2. **5G Technology**: As 5G networks roll out, the demand for high-performance capacitors has increased, with tantalum capacitors playing a key role in enabling faster data transmission.

3. **Satellite Communications**: Tantalum capacitors are used in satellite systems for their reliability in extreme conditions, ensuring consistent performance in space.

D. Medical Devices

In the medical field, the reliability and stability of tantalum capacitors are paramount:

1. **Implantable Devices**: Tantalum capacitors are used in pacemakers and other implantable devices, where long-term reliability is essential.

2. **Diagnostic Equipment**: These capacitors are found in imaging systems and diagnostic tools, contributing to accurate and reliable results.

3. **Monitoring Systems**: Tantalum capacitors support various monitoring devices, ensuring stable operation in critical healthcare applications.

E. Aerospace and Defense

The aerospace and defense industries require components that can withstand extreme conditions, making tantalum capacitors a preferred choice:

1. **Avionics Systems**: Tantalum capacitors are used in navigation and communication systems, where reliability is crucial for safety.

2. **Military Electronics**: These capacitors are employed in various military applications, including radar and communication systems, where performance and durability are essential.

3. **Space Exploration Technologies**: Tantalum capacitors are used in spacecraft and satellites, where they must perform reliably in harsh environments.

F. Industrial Applications

Tantalum capacitors are also utilized in various industrial applications:

1. **Automation and Control Systems**: These capacitors are used in control circuits for machinery and automation systems, ensuring stable operation.

2. **Power Supply Systems**: Tantalum capacitors are essential in power supply circuits, providing stable voltage and filtering capabilities.

3. **Robotics**: In robotics, tantalum capacitors support various electronic systems, contributing to the reliability and performance of robotic devices.

IV. Emerging Trends and Future Prospects

As technology continues to evolve, several trends are shaping the future of tantalum capacitors:

A. Innovations in Tantalum Capacitor Technology

Research and development efforts are focused on improving the performance and efficiency of tantalum capacitors, including advancements in materials and manufacturing processes.

B. Sustainability and Recycling Efforts

With growing concerns about the environmental impact of tantalum mining, the industry is exploring sustainable sourcing and recycling methods to reduce the ecological footprint of tantalum capacitors.

C. Market Growth and Demand Projections

The demand for tantalum capacitors is expected to grow, driven by advancements in consumer electronics, automotive technology, and telecommunications. Market analysts project significant growth in the coming years, particularly in emerging markets.

V. Challenges Facing the Tantalum Capacitor Industry

Despite their advantages, the tantalum capacitor industry faces several challenges:

A. Supply Chain Issues

The supply chain for tantalum is complex and can be affected by geopolitical factors, leading to potential shortages and price fluctuations.

B. Material Sourcing and Ethical Considerations

Tantalum is often sourced from regions with ethical concerns, raising questions about responsible sourcing and the impact on local communities.

C. Competition from Alternative Capacitor Technologies

As technology advances, alternative capacitor technologies, such as ceramic and aluminum capacitors, are gaining popularity, posing competition to tantalum capacitors.

VI. Conclusion

Tantalum capacitors play a vital role in various industries, from consumer electronics to aerospace and defense. Their unique properties, including high capacitance density and reliability, make them indispensable in modern technology. As the demand for advanced electronic devices continues to grow, the future outlook for tantalum capacitors remains positive, despite the challenges the industry faces. By addressing supply chain issues and focusing on sustainable practices, the tantalum capacitor industry can continue to thrive and support the advancement of technology.

VII. References

- Academic Journals

- Industry Reports

- Manufacturer Specifications and White Papers

In summary, tantalum capacitors are essential components in a wide range of applications, and their importance is only expected to grow as technology continues to evolve. Understanding the industries that utilize these capacitors provides insight into their critical role in shaping the future of electronics.