Latest Inductor Specifications

Latest Inductor Specifications

I. Introduction

Inductors are fundamental components in electronic circuits, playing a crucial role in energy storage, filtering, and signal processing. As passive components, they store energy in a magnetic field when electrical current flows through them. The importance of inductors cannot be overstated; they are essential in various applications, from power supplies to communication systems. This article aims to provide an overview of the latest specifications and trends in inductor technology, helping engineers and enthusiasts stay informed about advancements in this vital field.

II. Basics of Inductor Technology

A. Fundamental Principles of Inductance

1. **Definition of Inductance**: Inductance is the property of an electrical conductor that opposes a change in current. It is measured in henries (H), where one henry is defined as the inductance that produces one volt of electromotive force when the current through it changes at the rate of one ampere per second.

2. **Role of Magnetic Fields**: When current flows through an inductor, it generates a magnetic field around it. This magnetic field stores energy, which can be released back into the circuit when the current decreases. The ability of an inductor to store energy is directly related to its inductance value and the core material used.

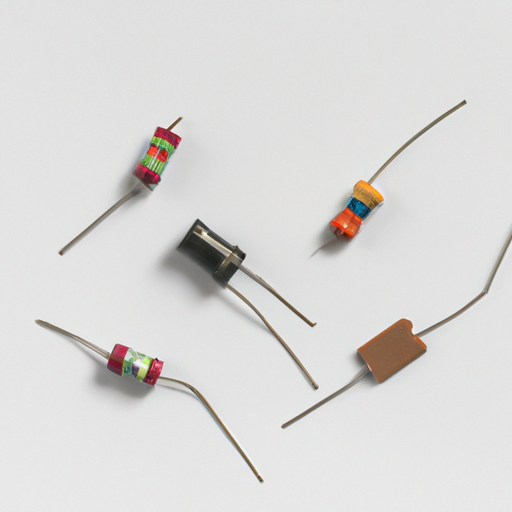

B. Types of Inductors

Inductors come in various types, each suited for specific applications:

1. **Air Core Inductors**: These inductors use air as the core material, making them suitable for high-frequency applications due to their low losses.

2. **Iron Core Inductors**: These inductors use iron as the core material, providing higher inductance values but with increased losses at high frequencies.

3. **Ferrite Core Inductors**: Ferrite cores are made from a ceramic material that offers high magnetic permeability, making them ideal for high-frequency applications.

4. **Toroidal Inductors**: These inductors have a doughnut-shaped core, which minimizes electromagnetic interference (EMI) and provides high inductance in a compact form.

5. **Chip Inductors**: These are small, surface-mount inductors used in modern electronics, offering high performance in a compact size.

III. Key Specifications of Inductors

Understanding the specifications of inductors is crucial for selecting the right component for a given application. Here are the key specifications to consider:

A. Inductance Value

1. **Measurement Units (Henries)**: Inductance is measured in henries (H), with common values ranging from microhenries (µH) to millihenries (mH).

2. **Tolerance Levels**: Inductors come with specified tolerance levels, indicating how much the actual inductance can vary from the stated value. Common tolerances range from ±5% to ±20%.

B. Current Rating

1. **Saturation Current**: This is the maximum current an inductor can handle before its inductance value begins to decrease significantly. Exceeding this current can lead to core saturation, resulting in reduced performance.

2. **RMS Current**: The root mean square (RMS) current rating indicates the maximum continuous current the inductor can handle without overheating.

C. DC Resistance (DCR)

DCR is the resistance of the inductor when a direct current flows through it. Lower DCR values are preferred as they result in less power loss and heat generation.

D. Quality Factor (Q)

The quality factor (Q) is a measure of the inductor's efficiency, defined as the ratio of its inductive reactance to its resistance at a specific frequency. A higher Q indicates lower energy losses.

E. Self-Resonant Frequency (SRF)

The self-resonant frequency is the frequency at which the inductor's inductive reactance equals its capacitive reactance, causing it to resonate. Beyond this frequency, the inductor behaves more like a capacitor.

F. Temperature Coefficient

The temperature coefficient indicates how the inductance value changes with temperature. This is crucial for applications where temperature variations are expected.

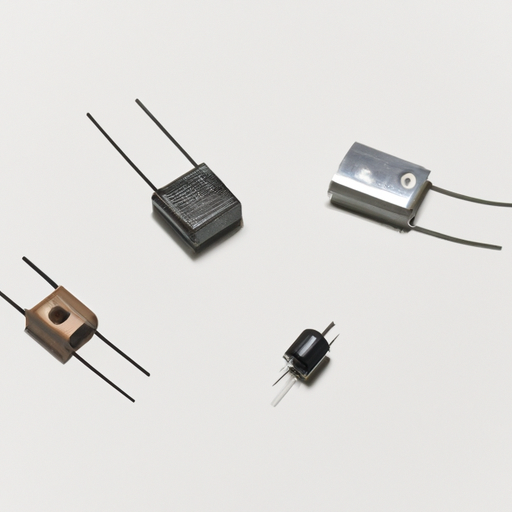

G. Size and Form Factor

1. **Surface Mount vs. Through-Hole**: Inductors come in various form factors, including surface mount and through-hole types. Surface mount inductors are preferred in compact designs, while through-hole inductors are often used in larger applications.

2. **Impact on PCB Design**: The size and form factor of inductors can significantly impact PCB layout and design, influencing the overall performance and efficiency of the circuit.

IV. Latest Trends in Inductor Technology

The inductor industry is continuously evolving, with several trends shaping the future of inductor technology:

A. Miniaturization and High-Density Packaging

As electronic devices become smaller and more compact, the demand for miniaturized inductors has increased. High-density packaging allows for more components to be integrated into smaller spaces, enhancing performance without compromising size.

B. Enhanced Materials and Manufacturing Techniques

1. **Use of Nanocrystalline Materials**: Nanocrystalline materials offer improved magnetic properties, allowing for higher inductance values and better performance at high frequencies.

2. **Advances in Ferrite Materials**: New ferrite materials are being developed to reduce losses and improve efficiency, particularly in high-frequency applications.

C. Integration with Other Components

1. **Inductor-Capacitor (LC) Filters**: The integration of inductors with capacitors to form LC filters is becoming more common, providing better performance in filtering applications.

2. **Power Inductors in Integrated Circuits**: The trend towards integrating inductors into ICs is gaining traction, allowing for more compact and efficient designs.

D. Environmental Considerations

1. **RoHS Compliance**: The Restriction of Hazardous Substances (RoHS) directive has led to the development of inductors that are free from harmful materials, promoting environmental sustainability.

2. **Lead-Free Soldering**: The shift towards lead-free soldering processes is influencing inductor manufacturing, requiring materials and designs that can withstand higher temperatures.

V. Applications of Inductors

Inductors are used in a wide range of applications, including:

A. Power Supply Circuits

Inductors are essential in power supply circuits, where they help regulate voltage and current, ensuring stable operation.

B. RF and Communication Systems

In RF applications, inductors are used in tuning circuits, filters, and oscillators, playing a critical role in signal processing.

C. Automotive Electronics

Inductors are used in various automotive applications, including power management systems, audio systems, and sensor circuits.

D. Consumer Electronics

From smartphones to televisions, inductors are integral to the performance of consumer electronics, ensuring efficient power delivery and signal integrity.

E. Renewable Energy Systems

Inductors are increasingly used in renewable energy systems, such as solar inverters and wind turbines, where they help manage power conversion and storage.

VI. Challenges and Considerations

While inductors are vital components, several challenges must be addressed:

A. Thermal Management

Inductors can generate heat during operation, necessitating effective thermal management strategies to ensure reliability and performance.

B. Electromagnetic Interference (EMI)

Inductors can be sources of EMI, which can affect the performance of nearby components. Proper shielding and layout techniques are essential to mitigate these effects.

C. Reliability and Longevity

The reliability of inductors is critical, especially in automotive and industrial applications. Manufacturers must ensure that their products can withstand harsh conditions and prolonged use.

D. Cost vs. Performance Trade-offs

Selecting the right inductor often involves balancing cost and performance. Engineers must consider the specific requirements of their applications to make informed decisions.

VII. Conclusion

In summary, inductors are essential components in modern electronic circuits, with specifications that significantly impact their performance. Understanding the latest trends and specifications in inductor technology is crucial for engineers and designers looking to optimize their designs. As technology continues to evolve, staying updated with the latest advancements will be key to leveraging the full potential of inductors in various applications.

VIII. References

1. Academic Journals

2. Industry Reports

3. Manufacturer Specifications and Data Sheets

By keeping abreast of the latest inductor specifications and trends, professionals in the electronics field can ensure they are making informed decisions that enhance the performance and reliability of their designs.