What is the production process of mainstream inductor pictures?

The Production Process of Mainstream Inductor Pictures

I. Introduction

Inductors are fundamental components in the world of electronics, playing a crucial role in various applications, from power supplies to radio frequency circuits. These passive components store energy in a magnetic field when electrical current flows through them, making them essential for filtering, energy storage, and signal processing. As the demand for high-quality inductors continues to grow, so does the need for accurate visual representations of these components—commonly referred to as inductor pictures. This article aims to explore the production process of mainstream inductor pictures, shedding light on their significance in design, manufacturing, and marketing.

II. Understanding Inductors

A. Basic Principles of Inductance

Inductance is defined as the property of an electrical conductor that opposes a change in current. When current flows through a coil of wire, it generates a magnetic field around it. This magnetic field can induce a voltage in the coil itself or in nearby conductors, which is the principle behind inductors. Inductors are widely used in electronic circuits to manage current flow, filter signals, and store energy.

B. Types of Inductors

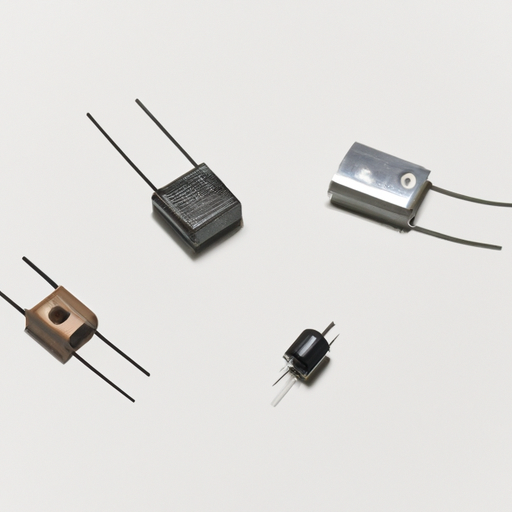

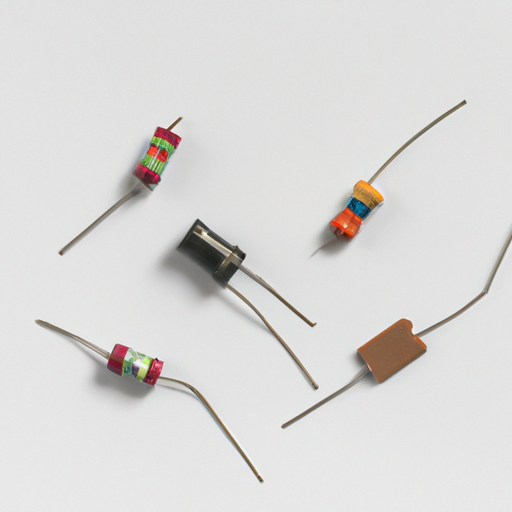

Inductors come in various types, each suited for specific applications:

1. **Air-core inductors**: These inductors do not use a magnetic core, making them suitable for high-frequency applications where low losses are essential.

2. **Iron-core inductors**: These inductors use iron as a core material, providing higher inductance values and better energy storage capabilities.

3. **Ferrite-core inductors**: Ferrite cores are made from a ceramic material that offers high magnetic permeability, making them ideal for high-frequency applications.

C. Applications of Inductors in Various Industries

Inductors find applications across multiple industries, including telecommunications, automotive, consumer electronics, and renewable energy. They are used in power supplies, filters, transformers, and energy storage systems, highlighting their versatility and importance in modern electronics.

III. The Role of Inductor Pictures

A. Importance of Visual Representation in Design

Inductor pictures serve as vital tools in the design process, allowing engineers and designers to visualize the component's physical attributes. Accurate images help in understanding the size, shape, and configuration of inductors, facilitating better design decisions.

B. Use of Inductor Pictures in Documentation and Marketing

In addition to aiding design, inductor pictures are essential for documentation and marketing purposes. They provide clear visual references for specifications, helping customers understand the product better. High-quality images can enhance marketing materials, making them more appealing to potential buyers.

C. Impact on Manufacturing Processes and Quality Control

Inductor pictures also play a role in manufacturing processes and quality control. Visual representations help ensure that the components are produced according to specifications, allowing for easier identification of defects or inconsistencies.

IV. The Production Process of Inductor Pictures

A. Conceptualization and Design

The production of inductor pictures begins with conceptualization and design. Engineers consider various factors, such as the intended application, size, and materials. Computer-Aided Design (CAD) software and simulation tools are commonly used to create detailed designs, allowing for prototyping and iteration before finalizing the product.

B. Material Selection

Material selection is a critical step in the production process. The choice of materials affects the inductor's performance, durability, and cost. Common materials include copper wire for winding, various core materials (like ferrite or iron), and insulation materials. Environmental considerations, such as sustainability and recyclability, are also taken into account during this phase.

C. Manufacturing Techniques

1. **Winding Processes**: The winding process is crucial for creating inductors. It can be done manually or through automated machines, with precision being key to achieving the desired inductance. Automated winding machines can produce consistent results, while manual winding may allow for more customization.

2. **Core Assembly**: The core assembly involves placing the wire windings around the core material. Different types of cores require specific assembly methods, and the choice of core material significantly impacts the inductor's performance.

3. **Soldering and Connections**: Reliable connections are essential for the functionality of inductors. Various soldering techniques are employed to ensure strong electrical connections, and quality control measures are implemented to verify the integrity of these connections.

D. Testing and Quality Assurance

Testing is a vital part of the production process. Various tests are conducted to ensure that the inductors meet performance standards. Inductance measurements, thermal testing, and other evaluations help identify any issues before the components are released to the market. Compliance with industry standards and certifications is also crucial for ensuring product quality.

V. Creating High-Quality Inductor Pictures

A. Photography Techniques

Capturing high-quality images of inductors requires specific photography techniques. Essential equipment includes a high-resolution camera, macro lenses for close-up shots, and a stable tripod. Proper lighting is crucial to highlight the details of the inductor, and a neutral background can help the component stand out.

B. Digital Editing and Enhancement

Once the images are captured, digital editing plays a significant role in enhancing their quality. Software tools like Adobe Photoshop or Lightroom can be used to adjust brightness, contrast, and color accuracy. Ensuring that the colors in the images accurately represent the physical components is vital for effective marketing and documentation.

C. Presentation and Usage

Inductor pictures can be presented in various formats, including digital and print. Best practices for incorporating images into documentation involve ensuring that they are clear, well-labeled, and placed in context with relevant information. In marketing, high-quality images can significantly impact customer engagement and sales.

VI. Challenges in the Production of Inductor Pictures

A. Technical Challenges in Capturing Accurate Representations

Capturing accurate representations of inductors can be challenging due to their size and intricate details. Achieving the right focus and depth of field is essential for showcasing the component's features.

B. Variability in Manufacturing Processes Affecting Image Quality

Variability in manufacturing processes can lead to differences in the final product, which may affect the quality of the images. Ensuring consistency in production is crucial for maintaining high-quality visual representations.

C. Balancing Detail with Clarity in Visual Representation

Finding the right balance between detail and clarity is essential when creating inductor pictures. Too much detail can overwhelm the viewer, while too little can fail to convey important information.

VII. Future Trends in Inductor Production and Imaging

A. Advances in Manufacturing Technology

The future of inductor production is likely to be shaped by advances in manufacturing technology, including automation and precision engineering. These innovations can lead to higher quality and more consistent products.

B. Innovations in Imaging Techniques

Emerging imaging techniques, such as 3D imaging and augmented reality, may revolutionize how inductor pictures are created and utilized. These technologies can provide more interactive and informative visual representations.

C. The Role of Artificial Intelligence and Machine Learning in Design and Production

Artificial intelligence and machine learning are poised to play significant roles in the design and production of inductors. These technologies can optimize design processes, predict performance, and enhance quality control measures.

VIII. Conclusion

Inductor pictures are more than just visual representations; they are essential tools in the electronics industry that facilitate design, manufacturing, and marketing. The production process of these images involves careful consideration of design, material selection, manufacturing techniques, and quality assurance. As technology continues to advance, the future of inductor production and imaging holds exciting possibilities that will enhance the quality and effectiveness of these critical components.

IX. References

- [1] "Inductors: Principles and Applications," Journal of Electronics, 2022.

- [2] "The Role of Visual Representation in Engineering Design," Engineering Design Review, 2021.

- [3] "Quality Control in Inductor Manufacturing," International Journal of Manufacturing Science, 2023.

- [4] "Advancements in Imaging Techniques for Electronics," Electronics Imaging Journal, 2023.